Grinding & mixing systems

Research has proven it:

Concentrated feed with a high grain content leads to better performance and lower-risk fattening runs with lower feeding costs.

The reason for cereals...

Grain mixtures are rich in valuable nutrients, tasty and above all easily digestible for your animals. Another very important plus, especially today, speaks for the farm's own grain mix:

You know exactly what you are feeding and thus ensure the quality of your products from the outset. Especially since grain is only subject to minor fluctuations in ingredients and quality. Of course, the grain must be properly prepared for the sensitive animal stomachs and fed in the correct dosage from the point of view of nutritional physiology.

HIMEL plant engineering

HIMEL plant engineering

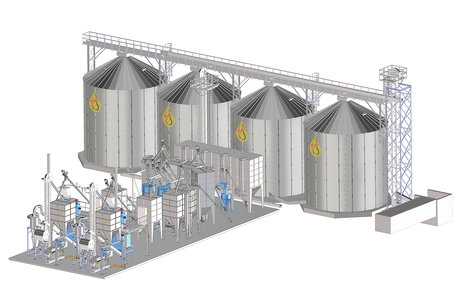

HIMEL supplies the technical prerequisites for the optimum yield of your farm from a single source. From the grain crusher and grist mill to the powerful compact mixer and the system solution. Enormous performance with convincing economic efficiency, high operational reliability, extremely stable design and the expansion possibilities through sensible accessories, make the large HIMEL machines the partner of choice for decades to come.

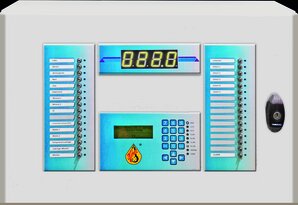

The matching HIMEL weighing computer turns the HIMEL feed mixer into a completely independent centre of feed preparation.

A complete range from one source - from the individual feed mixer to the complete feed preparation system.

You can rely on HIMEL - it is not for nothing that we are one of the leading suppliers in Europe with well over 1,000 feed mixing plants in Portugal, France, Holland, Luxembourg,Sweden, Iceland, Germany, Switzerland, Austria, Czech Republic, Slovakia, Hungary, Croatia, Serbia, Albania, Greece, Romania, Lithuania, Latvia, Estonia, Russia, Ukraine, Kazakhstan and Saudi Arabia.

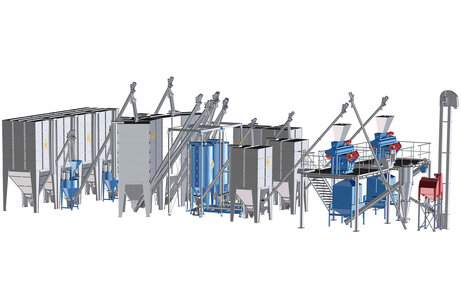

Mobile grinding & mixing plant

Fully automatic, mobile grinding & mixing plant with a capacity of approx. 1600kg/h

Four external augers fill the individual component silos from an existing grain store. The components are temporarily stored, from there they are dosed into the mills and then into the mixer.

The mixed feed is temporarily stored in a buffer container and can be emptied from there directly into a trailer or into big bags. Through an intermediate outlet, the mixed feed can also be filled into bags via the bagging scale.

Contact

HIMEL - Verkauf

D - 72393 Melchingen

- Tel: +49 7126 / 9299-0

- FAX: +49 7126 9299-1

- E-Mail: verkauf@himel.de

Wir beraten Sie gerne