Grain squeezers

HIMEL Grain squeezers

...transform hard grain into easily digestible crushed material with a large surface area, which the rumen utilises evenly and effectively. This way you can noticeably increase the milk and meat yield of your farm..

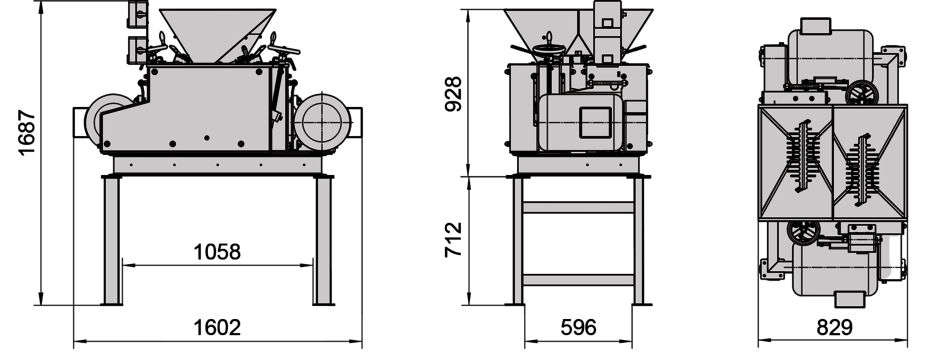

- With E. motors from 3.0 to 15kW, HIMEL grain crushers process up to 3600kg of crushed material per hour. In doing so, they consume considerably less energy (max. energy saving 50%) than conventional grain mills

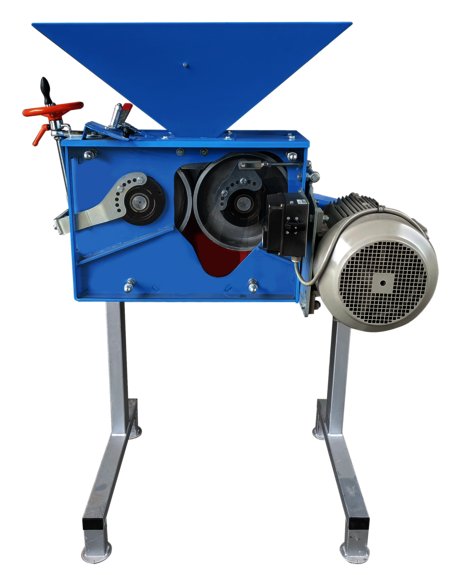

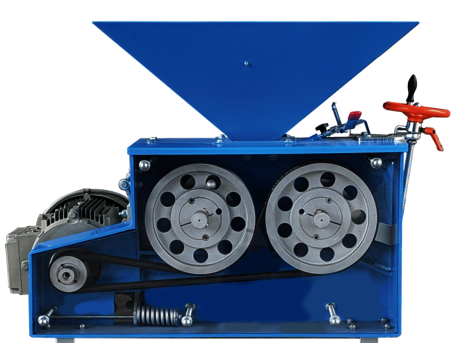

- Easy operation is ensured by the infinitely variable volume control for optimum power setting and handwheel adjustment for coarse or fine crushed material

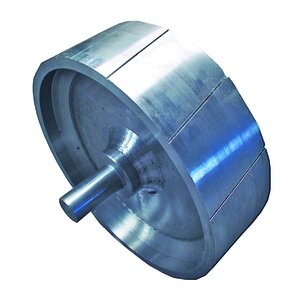

- Hardened cast iron rollers process hard crushing material with the synchronous drive to form high-conductivity chucks

- Large bearings and magnetic separators guarantee long service life and very smooth running

- Various automatic start and stop functions or a weighing computer round off the programme

- When feeding crushed grain, the feed quantity is reduced by up to 25%, with the same feeding result compared to uncrushed grain. Thus, one has significantly lower feeding costs and there is no need to buy expensive feed

- The grain husk is broken up and is therefore better digestible

- Crushed feed can be prepared fresh and therefore has no loss of vitamins and nutrients contained in the grain

- Stimulation of saliva formation to support the gastric juices, which are only present to a small extent; thus one achieves a better well-being of the animal

- Crushed grain retains its loose structure in the rumen, i.e. no lumps form

- The important raw fibre components are not destroyed and can be absorbed by the animal

- The digestion runs much slower and therefore more evenly

- Crushed grain is coarse-flaked, the rumen microbes work in a more targeted manner and thus a lower pH value fluctuation is achieved

- The respiratory openings of the animals do not become dusty and sticky. The animal eats better!

- With young animals you achieve an earlier feed intake

- Better development of the forestomach

| Technical data GMS | 101 | 151 | 201 | 251 | 301 | 401 | 501 | |

|---|---|---|---|---|---|---|---|---|

| Motor power | kW | 7,5 | 11 | 15 | 18,5 | 22 | 30 | 37 |

| Performance | from - | 450 | 650 | 800 | 1400 | 1900 | 2200 | 2500 |

| up to (kg) | 750 | 1100 | 1500 | 2000 | 2500 | 3000 | 3600 | |

| Recommended filter area | 6 | 8 | 10 | 12 | 14 | 15 | 16 | |

| *The performance values depend on the moisture and size of the material to be ground, the sieve insert and the suction and pressure length |