Horizontal mixer wagons

HX & H feed mixer wagons

Increasingly large livestock populations require mechanisation with a HIMEL feed mixer wagon

The user-friendly and robustly built HIMEL feed mixer wagon stands for:

- Low power requirement - smooth-running

- Optimal, homogeneous mixtures (TMR)

- No mixing of the feed thanks to the HIMEL agitator blade cutting system - precise mixing (DLG-tested)

- Round or square bales can be easily mixed in in portions, the V & Z series also processes whole bales

- High reliability - HIMEL feed mixers are successfully used on large farms with over 1000 animals

With the right composition of your mixed ration, the HIMEL feed mixer wagon allows you to achieve the following in the shortest possible time:

- Higher ingredients in the milk

- Higher weight gains from the basic feed

- Healthier herds

- No feed selection and empty feed troughs

- Reduced feed costs

- Reduced veterinary costs

The structure

- Steel, S355

- Bottom tray: 8 mm, from HX/H 88 10 mm

- Side walls: 6 mm

- Separate, stable chassis frame with attached mixer trough

- Side reinforcements as longitudinal and cross struts

- Strong support for the milling arms

- Hitch or towing jaw hitch

- Hitch height towing jaw 850 mm (with TÜV certificate)

- Stable support leg, hydraulic on request

- Cornered cradle bars (easy to replace)

- Infinitely adjustable lowering speed

- Large ejection opening

- 110 litre hydraulic oil supply

The chassis

The entire vehicle frame can be lowered over the axle using two large hydraulic cylinders. The H series is equipped with a rigid axle. Three cradle rods connect the chassis frame to the mixing hopper. This means that the weight can also be determined precisely during the milling process. All axles are TÜV-approved (25/40 km/h) and fitted with road tyres. With drawbar or hitch coupling.

The free-cutting high-performance rotary cutter

The centrepiece of the feed mixer wagon! The HIMEL tiller with powerful cast iron motor with gear ratio ensures fast and clean removal from the transport silo. The on-board hydraulics with automatic lowering and double-acting hydraulic cylinders guarantee high performance.

- Cutting width 160 cm, from HX 108 180 cm

- Cutting height up to 5, 5 m

- Free-cutting tiller thanks to additional row of blades outside the tiller arm

- Double-acting hydraulic cylinders prevent the tiller from "jumping"

- Large hydraulic motor rotating left and right

- Hydraulic motor and gearbox in the tiller

- Hydraulic lines protected in the tiller arm. Important for external filling

- Milling arm space-saving, on the side of the mixing trough

- The large opening in the rear wall of the mixer guarantees smooth operation without clogging

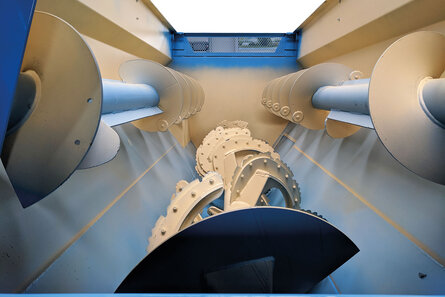

The mixing system

- Three-screw mixing system mixing system

- Open agitator blade shaft for particularly gentle preparation of the feed

- Cutting knives instead of crushing surfaces

- Two overhead mixing augers with bearings on both sides and rotating knives

- Both overhead mixing augers rotating inwards

- Long service life thanks to large bearings

- Counter-cutting for additional shredding of grass silage and straw

- Low power requirement

- Short mixing times

- Retention of the feed structure

- Only cutting and shredding, no mushing or pressing

- Screw diameter at the top approx. 480 mm

- Mixing auger diameter approx. 750 mm

- Wave diameter of the mixing auger 177.8 mm / 16 mm wall

The weighing system

- Weighing computer with 48 components, large display, simple menu navigation, up to 24 recipes for your individual feed formulation and PC interface

- Weight display with tare function, swivelling holder with splash guard and alarm signal for precise component use

- Large display and horn

- Component description in plain text (e.g. corn instead of component 1)

- Programming on PC possible

- Data feedback to the PC possible: target/actual comparison, consumption, deadline monitoring

- With app connection

The discharge

A discharge conveyor with hydraulically driven scraper floor ejects the mix in precise doses via a hydraulically controlled pusher. The standard front ejection on the right can be built to the left on request or supplied in a double-sided version (also rear ejection for the H series). The ejection takes place via automatic or hydraulic height adjustment.

- High discharge capacity thanks to chain conveyor

- Alternatively, a rubber discharge conveyor is available for smooth running

- Discharge quantity can be precisely controlled via slider position, travelling speed and rpm

- Discharge to the right, front standard, left, both sides or rear (H trolley only) on request

- Height adjustment is mechanical, automatic or hydraulic

- Exact, blockage-free and even dosing

- Hydraulic ejection slide with large display

- Chain conveyor can be supplied extended or shortened

- Fast-running motor on the chain conveyor for greater throwing distance possible

The operation

The on-board hydraulics can be operated conveniently from the tractor seat using the electromagnetic remote control or a flex cable control

- Remote flex cable control as standard

- All functions can be operated from the tractor seat

- Automatic lowering for the milling arm

- Electromagnetic control on request for all functions

- Clear layout, clear labelling

The gearbox and the hydraulics

The drive is provided by a stable planetary reduction gearbox, which directly rotates the large, smooth-running mixing auger with hardened special blades. The upper mixing augers, which rotate inwards on both sides, fill the mixing container optimally. The upper mixing augers have a robust chain drive. The large mixing container made of quality steel is additionally reinforced by longitudinal and cross struts.

- Large-dimensioned planetary gearbox

- Low-maintenance chain drive with chain tensioner

- On-board hydraulics with cast iron pumps and oil motors

- Pressure of the on-board hydraulics 160 bar

- Pressure of the automatic lowering system 180 bar (adjustable to tractor power) Pressure of the milling hydraulics max. 200 bar

- Hose rupture protection at all important points

- Large oil tank with oil filter

- Complete system suitable for plant-based hydraulic oil

- Milling speed 400 rpm with PTO shaft at 540 rpm

Basic equipment for milling mixer wagon HX & mixing wagon H

- Very low and clear construction

- Own on-board hydraulics with powerful cast hydraulic pump for maximum loads

- Reinforced mixing container with additional welded struts

- Mixer trough made of quality steel (St52) with additional cutting bars

- Support foot with hand crank for quick unhooking

- With chocks

- Safety reflectors

- Mixer trough made of quality steel (St52) with additional cutting bars

- Support foot with hand crank for quick unhooking steel (St52) with additional cutting bars

- Support foot with hand crank for quick unhooking

- With wheel chocks and safety reflectors

- Smooth operation and low drive power requirement thanks to large planetary gearbox, z. B. 9.5 m³ milling mixer wagon = 45 kW power requirement (DLG tested)

- Large oil tank with filter

- Hydraulic lines with hose rupture protection

- All HIMEL feed mixer wagons can be operated with biodegradable hydraulic oils

- Very high volume utilisation due to inward turning, upper mixing augers with counter-rotation

- Both upper augers prepared for screwing on knives for long mixing material

- Fast and homogeneous mixing thanks to the HIMEL agitator blade auger with closed supports and self-sharpening special knives

- Chain belt ejection at the front right with hydraulic slider and automatic height adjustment

- Easy operation via remote control, with flex cables (with electromagnetic remote control on request

- On request weighing computer for 24 components and 99 mixtures and PC data transfer (compatible with MS-Excel® )

- brake axle (TÜV-tested)

- Upgradable to hydraulic brake (8 km/h) or compressed air brake (25 km/h)

- Hitch or drawbar coupling (TÜV-tested on request)

- Prepared for TÜV testing

Basic equipment for milling mixer wagon HX

- Side milling arms with double-acting lifting cylinder

- With safety rotating light

- High milling performance for grass and maize thanks to free-cutting high-performance tiller

- Tiller with high torque thanks to powerful cast motor with gearbox, left and right turning

- Cutting width 1.60 m, from HX 108 1, 80 m

- Hydraulic automatic lowering system, so the tiller does not get stuck

- 2 oil pressure gauges

- Hydraulic lines are protected, so front loader filling is also possible

- Vehicle frame can be lowered over the axle using hydraulic cylinders

- Stable, separate chassis frame with stainless steel weighing device

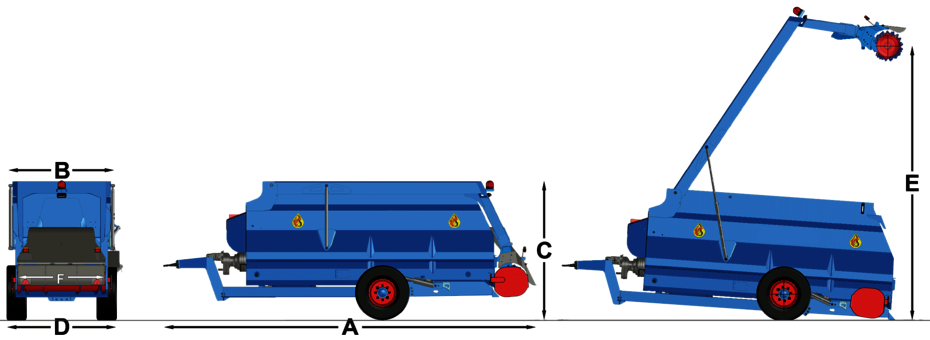

Dimensions and contents of feed & milling mixer wagons H and HX

| Typ | Inhalt | (A) Länge | (B) Breite oben | (C) Höhe | (D) Spurbreite | Gewicht | Leistung |

|---|---|---|---|---|---|---|---|

| (m³) | (m) | (m) | (m) | (m) | (kg) | (kW) | |

| HX 68 | 6,80 | 6,04 | 1,67 | 2,21 | 1,90 | 4770 | 30 |

| HX 88 | 8,80 | 6,29 | 2,07 | 2,29 | 2,00 | 5100 | 37 |

| HX108 | 10,80 | 6,54 | 2,07 | 2,39 | 2,00 | 6000 | 50 |

| HX128 | 12,80 | 7,28 | 2,07 | 2,69 | 2,15 | 7020 | 65 |

| HX148 | 14,80 | 7,28 | 2,07 | 2,80 | 2,20 | 7040 | 75 |

| H 68 | 6,80 | 5,25 | 1,67 | 2,26 | 1,90 | 3700 | 25 |

| H 88 | 8,80 | 5,50 | 2,07 | 2,34 | 2,00 | 4050 | 35 |

| H108 | 10,80 | 5,75 | 2,07 | 2,44 | 2,00 | 4800 | 43 |

| H128 | 12,80 | 6,40 | 2,10 | 2,56 | 2,20 | 5000 | 45 |

| H148 | 14,80 | 6,40 | 2,10 | 2,69 | 2,20 | 5105 | 55 |